Rig Floor Maintenance

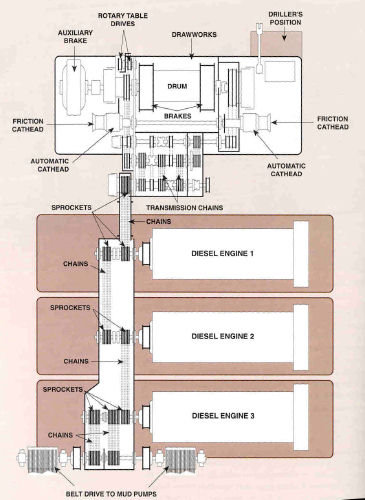

Rig floor maintenance includes inspecting, adjusting, and servicing equipment used during drilling operations. This work is done on parts such as the drawworks, rotary table, catheads, tongs, air hoists, and wire rope. These parts must be checked regularly to make sure they are working properly and safely.

Servicing this equipment may involve checking for worn or damaged parts, tightening loose connections, applying lubrication, and testing moving parts. Maintenance work helps prevent breakdowns and reduces the risk of injury to workers.

Potential Hazards

- Being struck by tubulars, equipment, and tools

- Slips, trips, and falls

- Being caught in moving equipment

- Getting fingers and hands pinched

- Sprains and strains

Possible Solutions

- Wear personal protective equipment (such as hard hats, work gloves, safety shoes, and eye protection).

- Be aware of the slipping and falling hazards when performing maintenance on the drilling floor.

- Keep all work areas clean and clear of oil, tools, and debris.

- Use non-skid surfaces where appropriate.

- Use proper lockout/tagout procedures.

- Seek assistance when moving awkward and heavy guards and covers.

- Maintain all machinery free of leaks by regular preventive maintenance and repairing when necessary.

Knowledge Check Choose the best answer for the question.

8-2. What is one common hazard workers face on the rig floor during maintenance?

You forgot to answer the question!