Drilling Ahead Safety

Preparing to Break Out Pipe

To begin breaking out the pipe, the driller stops the rotation of the drill string. Then, the driller uses the drawworks to raise the drill string until the kelly is pulled up and cleared from the rotary table. This step is necessary before any part of the pipe can be disconnected.

Once the kelly is out, the driller shuts down the mud pump or pumps. Stopping the flow of drilling fluid helps prevent pressure buildup while disconnecting the pipe.

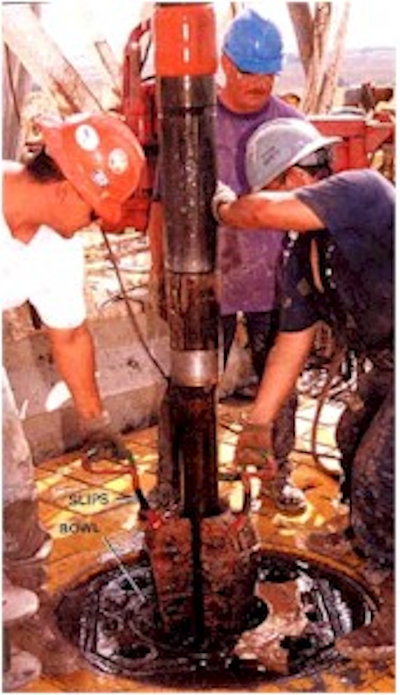

At this point, the floor hands step in to place the slips around the joint of the pipe. Slips are tools used to hold the drill string in place and prevent it from falling back into the well.

Once the slips are in place and secure, the tongs are latched onto the pipe. One set of tongs is connected to the tool joint above the connection, and the other set is connected below. These tongs are used to apply torque and unscrew the pipe sections from each other. This step requires teamwork, coordination, and attention to safety procedures.

Potential Hazards

- Pinching fingers or other body parts between slips or slip handles and rotary table

- Experiencing muscle strain from improper lifting technique

- Pinching fingers when latching the tongs onto the pipe

Possible Solutions

Implement effective, safe work procedures for using slips and tongs, which include:

- Proper finger and hand placement on slip handles and tong handles

- Proper stance and slip lifting techniques

- Proper tong latching techniques

Knowledge Check Choose the best answer for the question.

5-1. What are listed as potential hazards when preparing to break out pipe?

You forgot to answer the question!