Drilling Ahead Safety

Drilling ahead is the phase in which the rig actively drills the wellbore to reach target depths.

Drilling Ahead Equipment

Drill Bit: The drill bit is the tool at the bottom of the drill string that cuts through rock to deepen the wellbore. It rotates to grind or crush rock formations and is selected based on the type of formation. Common types include roller cone bits and PDC (polycrystalline diamond compact) bits.

- Breaks and penetrates rock formations

- Equipped with nozzles for mud flow

- Requires regular inspection and replacement

- Drill Bit: The tool that cuts through rock at the bottom of the hole

- Drill Collars: Heavy, thick-walled pipes that add weight and keep the bit steady

- Stabilizers: Tools that help keep the drill string centered in the hole

- Measurement Tools: Sensors that provide real-time data like pressure, temperature, and angle

Drill String: The drill string is a series of connected tubular steel pipes that extend from the surface to the drill bit. It transmits rotational force and drilling fluid to the bit. It is rotated either by a top drive system mounted on the derrick or by a rotary table at the rig floor.

- Includes drill pipe, drill collars, and the bottomhole assembly (BHA)

- Delivers torque to the bit

- Carries drilling fluid to and from the wellbore

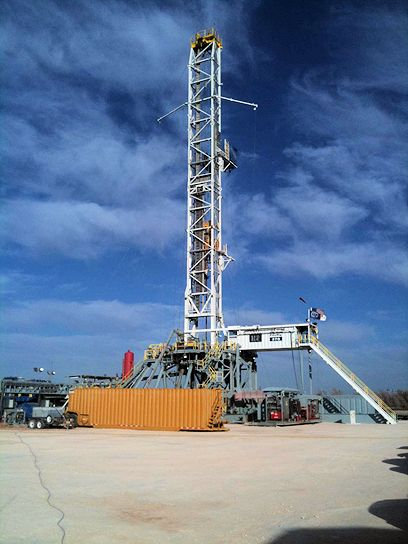

Top Drive: A top drive is a motorized system mounted on the derrick that rotates and hoists the drill string. It allows for more efficient and safer drilling than the kelly and rotary table system.

- Automates rotation and vertical pipe handling

- Reduces manual labor and speeds up drilling

- Often used with an Iron Roughneck to handle pipe connections

Kelly and Rotary Table: This traditional manual system rotates the drill string using a square or hexagonal kelly pipe through a rotary table on the rig floor. Though still in use, it is being replaced by top drives in many operations.

- Kelly fits into and is turned by the rotary table

- System allows vertical movement while rotating

- Requires manual connection and disconnection

Drill Pipe Stands: Drill pipe stands are vertical sections of drill pipe, usually consisting of two or three connected joints, that are set aside temporarily during tripping operations.

- They are typically stored vertically in the derrick’s fingerboard, organized and held in place until needed again.

- They improve workflow and safety by minimizing the number of connections that must be made or broken one by one at the drill floor.

Mud Pumps: Mud pumps are high-pressure pumps that circulate drilling fluid down the drill string and back up the well. This fluid performs several critical functions in the drilling process.

- Cools and lubricates the drill bit

- Removes rock cuttings from the hole

- Maintains wellbore stability and pressure control

Knowledge Check Choose the best answer for the question.

4-1. Why is a top drive preferred over a kelly and rotary table system in modern drilling?

You forgot to answer the question!