Casing Operations Safety

Introduction

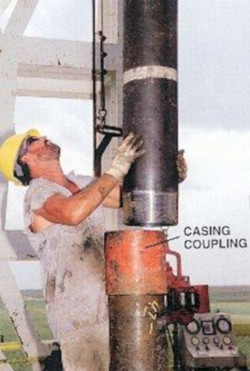

Casing is a heavy steel pipe that is typically larger in diameter and longer than drill pipe and is installed in sections to line the recently drilled portion of a borehole. Once the casing is set in place, it is secured by pumping cement into the annular space between the casing and the wellbore.

Proper casing installation is critical to the safety, integrity, and long-term performance of a well. Casing provides structural support, isolates subsurface formations, and allows drilling and production operations to continue safely and efficiently.

The primary purposes of casing include:

- Preventing the walls of the borehole from caving in or collapsing.

- Providing a smooth, stable internal surface of the borehole for drilling, logging, and production operations.

- Preventing the movement of fluids, gases, or pressure between different subsurface formations.

- Preventing fluid loss into the formation and protecting groundwater from contamination.

- Aiding in well control and helping prevent blowouts by allowing proper installation of pressure-control equipment.

Casing operations occur at multiple stages throughout the drilling process. These typically begin with surface casing, followed by one or more intermediate casing strings, and conclude with the production casing installed during well completion. Each casing string serves a specific purpose and introduces unique operational and safety challenges.

While casing size, weight, and installation methods vary depending on the well design and formation conditions, casing operations generally follow a common sequence of activities. Understanding this sequence helps workers anticipate hazards and apply appropriate safety controls.

The primary activities involved in casing operations typically include:

- Installing casing tools, such as elevators, slips, tongs, and handling equipment.

- Running casing into the hole using hoisting equipment and controlled handling techniques.

- Installing casing accessories, including centralizers, float equipment, and scratchers.

- Circulating and cementing the casing to secure it in place and isolate formations.

Knowledge Check Choose the best answer for the question.

7-1. A pipe that is usually larger in diameter and longer than drill pipe and is used to line the recently drilled section of a borehole is called a _____.

You forgot to answer the question!