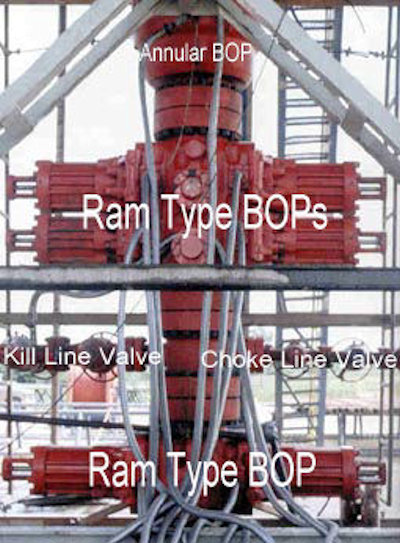

Installing and Testing BOPs, Accumulator, and Choke Manifold

Installing and testing the Blowout Preventers (BOPs), accumulator system, and choke manifold are critical well control activities. These systems must function properly to safely control formation pressures and prevent uncontrolled releases of hydrocarbons. Because these components are heavy, complex, and operate under high pressure, installation and testing present significant hazards if not properly managed.

Potential Hazards

- Being crushed or struck by falling equipment if hoisting slings, shackles, or lifting points fail during installation of the BOP stack or related components.

- Being struck by, pinched by, or caught between equipment while aligning, stabbing, or bolting together BOP components, valves, or manifolds.

- Being struck by whipping hoses or sprayed with hydraulic fluid if seals, fittings, or hydraulic lines fail during pressure testing.

- Exposure to high-pressure energy during accumulator or choke manifold testing.

Possible Solutions

- Ensure all personnel stand clear of suspended or hoisted equipment and use tag lines to control loads during lifting and positioning.

- Coordinate all hoisting and installation tasks with the rig crew, crane operator, and service personnel using clear communication and established hand signals or radios.

- Inspect hoisting slings, shackles, hooks, and lifting points for wear, damage, or improper ratings before any hoisting operation.

- Require all personnel to wear appropriate Personal Protective Equipment (PPE), including hard hats, gloves, eye protection, steel-toed boots, and flame-resistant clothing.

- Establish exclusion zones and ensure workers stand clear of pressurized lines, hoses, and fittings during accumulator and pressure testing procedures.

- Verify pressure ratings and compatibility of hoses, fittings, and components before testing begins.

- Follow written testing procedures and manufacturer recommendations for BOPs, accumulators, and choke manifolds.

Knowledge Check Choose the best answer for the question.

9-5. What type of accident might happen if there is a seal or hydraulic line failure during pressure testing?

You forgot to answer the question!