Actions

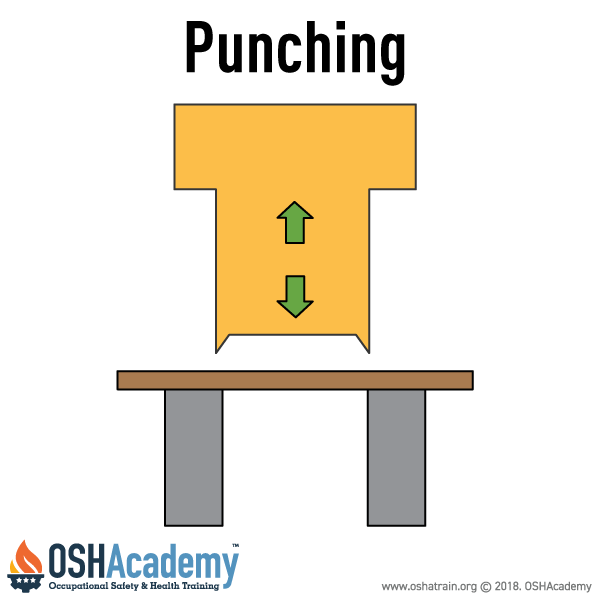

Punching

Punching is a common mechanical process in metal fabrication that involves applying power to a slide or ram to perform tasks such as blanking, drawing, or stamping. This action typically involves forcing a punch through the material and into a die to create holes or shapes.

Key Features of Punching Actions

The key features of punching actions include the following:

- The punching process presents significant safety hazards, especially at the point of operation where the stock is manually inserted, positioned, and removed.

- The types of injuries that may occur due to punching actions include crushing injuries, amputations, and hand trauma including fractures, lacerations, and severe bruising from accidental contact.

- Risks of injuries are heightened by the speed and force involved in punching operations.

Examples

- Power Presses: These machines use a powered ram to punch holes or form shapes in sheet metal or similar materials.

- Hazard: An operator reaches in to adjust the material and the ram descends unexpectedly, resulting in a finger amputation.

- Best Practice: Use presence-sensing devices or two-hand controls to keep hands away from the danger zone during operation.

- Iron Workers: These are versatile machines used for punching, shearing, and notching metal.

- Hazard: A worker manually aligns a large piece of steel for punching, but misalignment causes the piece to shift, crushing the operator’s hand.

- Best Practice: Use mechanical feeds or clamps to secure material, and ensure the machine is equipped with guards to prevent hand access to the point of operation.

Knowledge Check Choose the best answer for the question.

1-8. What happens during the punching process in metal fabrication?

You forgot to answer the question!