Actions

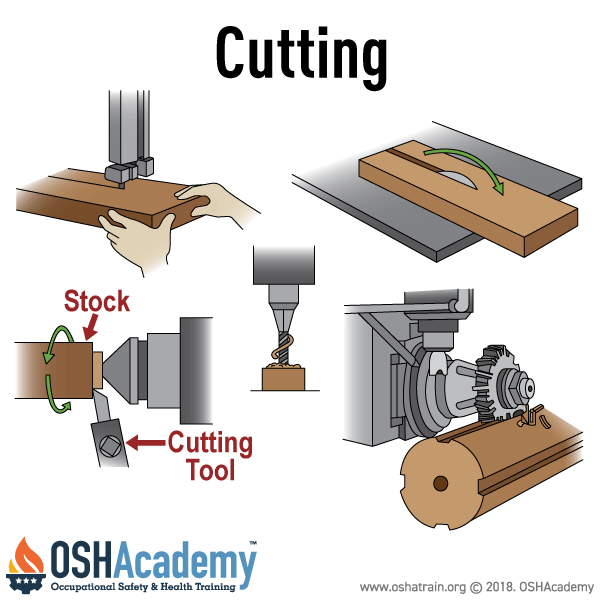

Cutting

Actions involve operations where material is removed from a workpiece by means of sharp tools.

There are five primary cutting actions used in machinery, each of which can expose workers to serious injuries:

- Rotating cutting – Common in machines like circular saws, grinders, and milling machines. The rotating blade or cutter slices through the material, making rotating cutting particularly dangerous of causing lacerations and amputations.

- Reciprocating cutting – Found in machines like jigsaws or some types of metal shears. The blade moves back and forth, which can trap fingers or hands in the motion.

- Transverse cutting – Occurs when a blade or cutter moves across a surface. This is typical in certain automated cutting systems and can be unpredictable without proper guarding.

- Shearing – Seen in guillotine-style cutters or metal shears, where two blades pass each other to cut material. This action can easily amputate fingers or hands if safety procedures are not followed.

- Abrading – Uses friction, such as grinding or sanding, to wear down material. While not a traditional cutting motion, it still removes material and can eject particles at high speed.

Key Features of Cutting Actions

The key features of cutting actions include the following:

- Cutting actions occur at the point of operation, where the tool contacts the material—this is the most hazardous location.

- Cutting can cause severe injuries such as lacerations, crushed fingers, or amputations.

- Flying chips or scrap from cutting may strike workers in the eyes or face.

- Entanglement risks exist if loose clothing, gloves, or hair are near rotating or moving tools.

The danger of cutting action is highest at the point of operation—the location on the machine where the cutting tool meets the material. Injuries here can include cuts, crushed fingers, or even amputations. In addition, flying chips or scrap material can become airborne, risking injury to the eyes or face.

Examples of machinery that involve cutting hazards include:

- Band saws – Used in woodworking and metalworking; the continuous blade can cause deep cuts or amputations.

- Circular saws – High-speed spinning blades can eject wood or metal fragments and cause severe lacerations.

- Boring or drilling machines – Bits can snag loose clothing or hair, pulling the operator into the machine.

- Turning machines (lathes) – Workpieces or cutting tools can break loose or cause entanglement hazards.

- Milling machines – The rotary cutters can grab or eject material unexpectedly if not properly guarded.

- Grinders – Commonly used for finishing surfaces; grinding wheels can shatter or eject hot particles, leading to eye and skin injuries.

Knowledge Check Choose the best answer for the question.

1-7. Why is rotating cutting action particularly dangerous?

You forgot to answer the question!