Motions

Transverse Motions

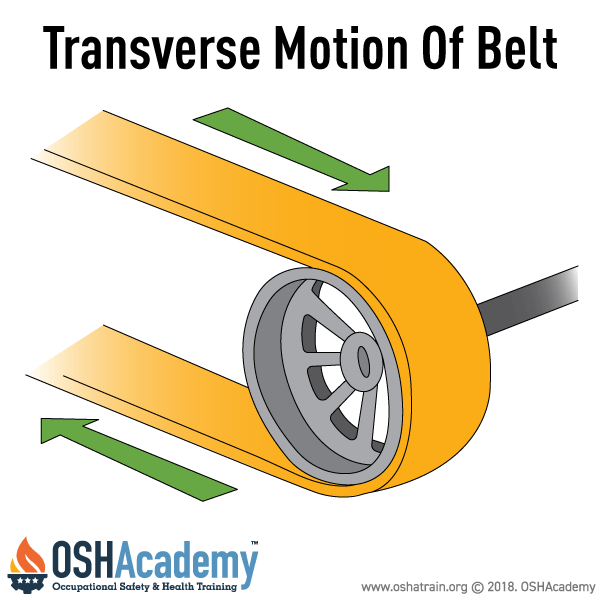

Transverse motions involve movement in a straight, continuous line, such as the linear travel of a conveyor belt or the back-and-forth action of a reciprocating saw.

These motions create hazards when workers come into contact with pinch or shear points, where moving parts meet stationary ones or other moving components. The risks include cuts, lacerations, or amputations, particularly if workers are not trained or if safety guards are absent.

Key Features of Transverse Motions

The key features of transverse motions include the following:

- Motion is in a continuous, linear path—either forward/backward or side-to-side.

- They are common in conveyors, saws, and other material-handling equipment.

- They create pinch and shear points where moving parts meet stationary or other moving parts.

- They pose serious risks of cuts, lacerations, or amputations if safety guards are not in place.

Examples

These examples show how pinch or shear points can cause serious injuries:

- Conveyor Belts: Conveyor systems, common in warehouses and manufacturing plants, move materials along a fixed path. If a worker attempts to clear a jam or adjust an item on a moving conveyor without stopping it, their hand or clothing could be caught in a pinch point (e.g., where the belt meets a roller), leading to severe cuts or limb entrapment. For example, a warehouse worker trying to dislodge a stuck package may suffer a crushed hand if it gets pulled into the conveyor mechanism.

- Reciprocating Saws: Used in construction and woodworking, reciprocating saws have blades that move back and forth rapidly. If a worker’s hand slips or the material shifts, the blade can cause deep lacerations or amputations. An example is a carpenter cutting through wood who loses control of the saw, resulting in a severe cut to their hand when the blade contacts their fingers.

Safety measures for transverse motions include installing guards to cover pinch and shear points, using emergency stop buttons, and ensuring workers maintain a safe distance from moving parts. Regular training on machine operation and the use of personal protective equipment (PPE), such as gloves, can further reduce risks.

Knowledge Check Choose the best answer for the question.

1-6. What kind of motion defines transverse movement in machinery?

You forgot to answer the question!