Actions

Bending

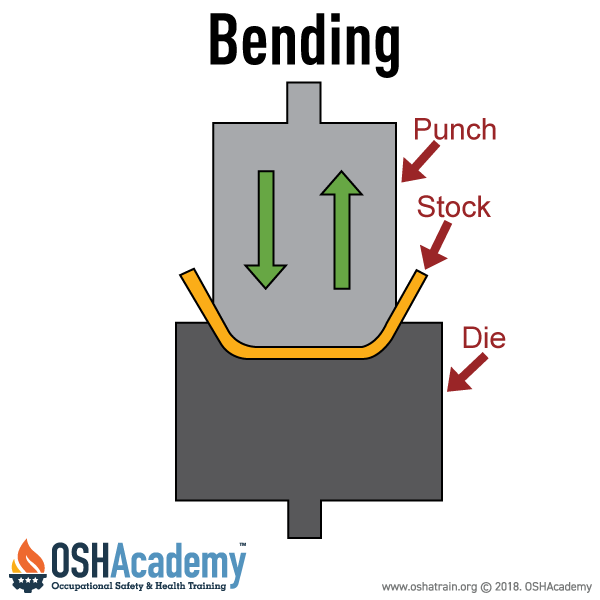

Bending is a mechanical process where power is applied—typically using a press or brake—to form metal or other materials into curves, angles, or complex shapes.

Key Features of Bending Actions

The key features of bending actions include the following:

- Bending is often accomplished with a punch and die system, where the punch pushes the material into the die to shape it.

- Bending is commonly used in industries that manufacture components for automobiles, appliances, construction materials, and more.

- Bending hazards occur primarily at the point of operation, where the material is inserted, held, and removed.

- Because this area involves high-force movement, workers face serious risks such as crushing, amputations, and pinching injuries.

An operator can reduce the risk of injury on a press brake by following these key safety practices:

- Use Machine Guards and Safety Devices. Always ensure point-of-operation guards or presence-sensing devices (like light curtains) are installed and working.

- Keep Hands Clear of the Die Area. Use push sticks, hand tools, or foot controls to avoid placing hands near the moving parts.

- Receive Proper Training. Operators must be trained on how to safely set up, operate, and maintain the press brake.

- Follow Lockout/Tagout (LOTO) Procedures. Before maintenance or setup, lock out and tag out the machine to prevent accidental startup.

- Check the Press Brake Before Use. Inspect the machine daily for any signs of damage or wear. Report any issues immediately.

- Stay Focused and Avoid Distractions. Remain alert during operation. Distractions can lead to serious injuries.

- Use Correct Settings and Dies. Match the machine settings and die types to the job. Incorrect setups can cause the material to shift or eject unexpectedly.

Examples

- Power Presses: These machines apply a strong, quick force to shape metal into forms like brackets or panels. The fast-moving slide can trap fingers or hands if safety devices are disabled or removed.

- Press Brakes: Used specifically for bending sheet metal by pressing it between a punch and die. Hazards include hand injuries during stock alignment and the risk of crushing due to the powerful downward motion.

- Tubing Benders: These machines shape metal or plastic tubing by bending it around a form or die. Hazards arise if the operator’s hands are caught in the mechanism or if the tubing springs back unexpectedly.

Knowledge Check Choose the best answer for the question.

1-10. How can an operator reduce the risk of injury on a press brake?

You forgot to answer the question!