Motions

In-running Nip Points

In-running nip points are hazardous areas where rotating parts of machinery come into close proximity or contact, creating points that can trap, crush, or shear materials, body parts, or clothing.

Entanglement Hazards

These hazards arise from the interaction of rotating components, either with each other or with fixed parts, and are common in various industrial machines.

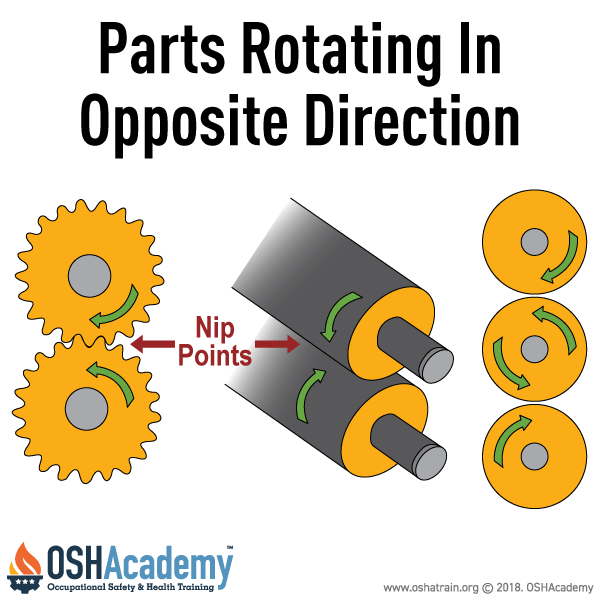

There are three primary types of in-running nip points, each with distinct mechanisms and examples.

- Parallel rotating parts: This type of nip point occurs when two parts rotate in opposite directions with their axes parallel, often in contact or close proximity, creating a pinching or crushing hazard. The danger is most pronounced when materials or body parts are drawn into the contact point.

- Parts rotating in opposite directions: For example, in a rolling mill, two cylindrical rollers rotate toward each other to flatten or shape metal. If a worker’s hand or clothing is caught between the rollers, it can be pulled in and crushed. This hazard is also present in machines with intermeshing gears, where teeth from opposing gears create nip points that can trap fingers or tools, leading to severe injury.

- Stock fed between rolls: Machines like calenders (used in paper or textile processing) or rolling mills feed material (stock) between two rotating rolls, creating nip points. For instance, in a paper calender, the paper is squeezed between rollers to achieve a smooth finish, but a worker’s hand or loose clothing can be pulled into the same nip point, resulting in crushing or entanglement. Proper guarding and training are essential to prevent such incidents.

Examples of in-running nip points include the following:

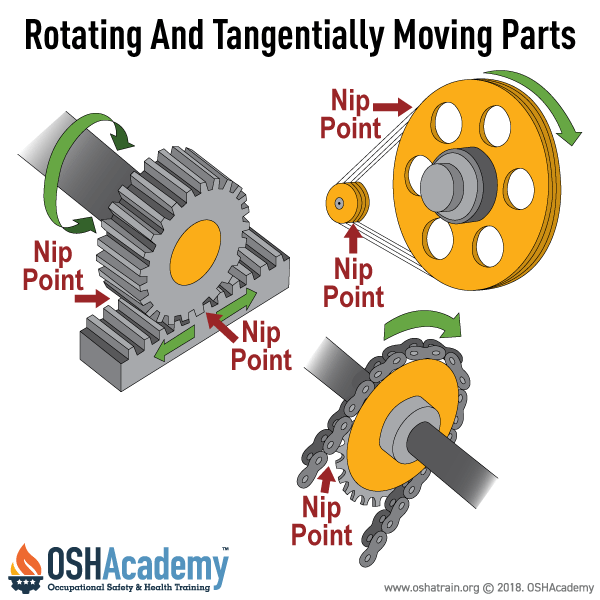

- Tangentially moving parts: Nip points are also formed at the point of contact between a rotating part and a tangentially moving component, where one part moves linearly while the other rotates. These points are particularly dangerous because they combine rotational and linear forces, creating a pulling action that can trap objects or body parts.

- Power transmission belt and pulley: A common example is the point where a belt meets its pulley in a conveyor or motor system. The belt moves tangentially while the pulley rotates, creating a nip point that can catch fingers, clothing, or hair. For instance, a loose sleeve caught in this nip point can pull a worker’s arm into the machinery, causing severe injury or entanglement.

- Chain and sprocket: In chain-driven systems, such as those in bicycles or industrial conveyors, the chain moves tangentially while the sprocket rotates. The point where the chain engages the sprocket’s teeth forms a nip point that can crush or sever fingers or catch loose items like gloves, leading to serious accidents.

- Rack and pinion: In a rack-and-pinion system, the rotating pinion gear meshes with a linearly moving rack, creating a nip point at their contact. This is common in machinery like CNC tables or steering systems. If a worker’s hand is near the meshing point, it can be pinched or crushed, resulting in severe injury.

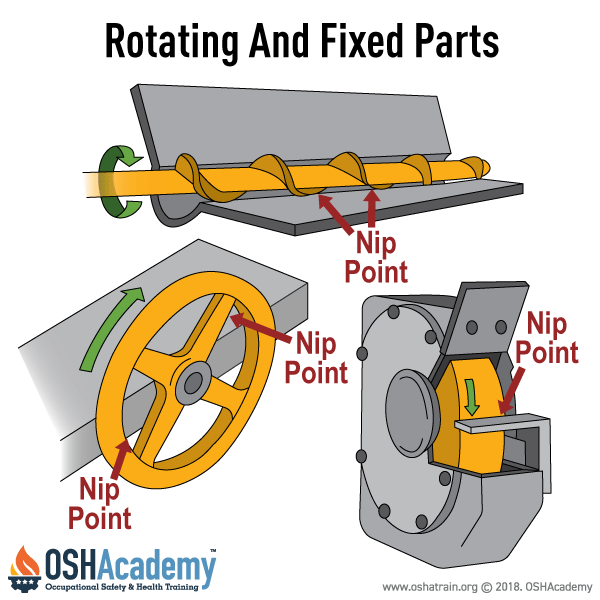

- Rotating and fixed parts: Nip points between rotating and fixed parts create shearing, crushing, or abrading actions due to the relative motion between a moving component and a stationary one. These hazards are particularly insidious because the fixed part can amplify the force of the rotating component.

- Screw conveyors: Screw conveyors, used to move materials like grain or powder, feature a rotating auger within a fixed trough. The narrow gap between the auger and the trough wall forms a nip point that can shear or crush anything caught in it, such as a worker’s hand or tool during maintenance or cleaning.

- Periphery of an abrasive wheel and an incorrectly adjusted work rest: In grinding machines, an abrasive wheel rotates at high speed next to a work rest, which supports the material being ground. If the work rest is too far from the wheel, a nip point forms that can pull in fingers, clothing, or the workpiece itself, causing abrasion, burns, or amputation. Proper adjustment of the work rest (typically within 1/8 inch of the wheel) is critical to minimizing this hazard.

Knowledge Check Choose the best answer for the question.

1-4. How does a nip point form between a belt and pulley?

You forgot to answer the question!