Wire Rope or Cable Sling

Inspection

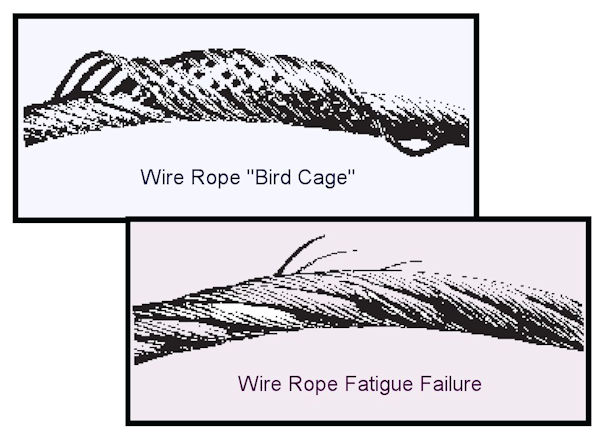

Check each sling individually for the following conditions: wear, broken wires, heat damage, corrosion, kinks or doglegs, eye deformation, or damage to the end fitting.

Mark any damage on the inspection form, mark the sling, and remove it from use.

Start with the end eye or fitting. Inspect the inside of the eye for wear or broken wires. Look the eye over carefully to determine if it has been stretched or pulled over a large object. See if there is any evidence of knotting or twisting of the eye.

Inspect the swaged fittings for cracks or bending, paying close attention to where the wires enter the fitting.

Move to the body of the sling. Does it show any deformation, such as kinking, knots, or crushing? Make sure the sling has not been tightened around a sharp corner that would cut or break the cable.

Ensure that there are not more than five randomly distributed broken wires in one strand in one lay length of rope. If more than 10 broken wires are found in one rope lay or the sling exhibits other damage, it should be taken out of service and destroyed.

Knowledge Check Choose the best answer for the question.

7-2. While inspecting a wire rope, you notice there are five broken wires in one strand in one lay length of rope, what should be done?

You forgot to answer the question!