Gates

The gate is a moveable barrier designed to protect the operator from injury at the point of operation before a machine cycle can begin.

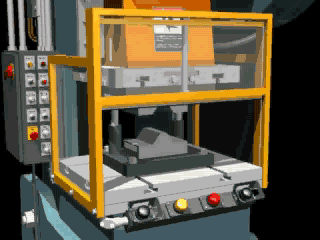

Gate for Punch Press

These gates are often designed to move in synchronization with each machine cycle. To ensure safety, the gate must be interlocked, meaning the machine will not start its cycle unless the gate is in the proper closed position.

Gate Types

They are commonly used with power presses and come in two main types: Type "A" and Type "B."

- Type "A" Gates: These close prior to the machine cycle and remain closed during the entire cycle. This type provides full protection during the entire operation.

- Type "B" Gates: These also close before the machine cycle starts but may open during the return stroke of the press. They offer protection mainly during the downward (hazardous) stroke.

Key Safety Features and Guidelines

The key features of a gate include the following:

- It must fully close before the press can operate.

- It must prevent any body parts, such as hands or fingers, from entering the point of operation during the die-closing portion of the cycle.

- It should be tested regularly to ensure the interlock is functioning properly.

Example

A mechanical power press in a metal stamping operation uses a Type "A" gate. The operator loads a metal blank into the press, and the gate automatically descends and locks in place. Only once the gate is fully closed does the press complete the stamping cycle. If the gate is obstructed and cannot close, the press remains idle, preventing potential injury.

In some settings, gates are part of a larger perimeter safeguarding system. This means the gate doesn't just protect the operator, but also guards against unauthorized or accidental access by pedestrians. For example, a gate at the entrance of a robotic welding cell ensures no one can enter while the robot is active.

| Safeguarding Action | Advantages | Limitations |

|

Concurrent use of two hands on separate controls prevents hands from being in the danger area when machine cycle starts |

Operator's hands are away from danger area Can be adapted to multiple operations No obstruction to hand feeding Does not require adjustment for each operation |

Operator may try to reach into danger area after tripping machine Some trips can be rendered unsafe by holding with arm or blocking, thereby permitting one-hand operation Protects only the operator May require special fixtures |

"A" Gate Sequence of Operation. Type "A" Gates protect the operator during the entire machine stroke. This means the gate will not open until after the crankshaft rotation is complete (360°) and the machine is stopped at top dead center. Although Type "A" Gates can be used on either part or full revolution clutch presses, best safety practice is the "A" gate should be used only on full revolution clutch presses.

The "A" gate is designed to enclose the point of operation before the press stroke can be started, and it must remain enclosed until all slide motion has stopped. The following is a typical sequence of operation of a complete cycle on a press which uses an "A" gate.

- Initiate the cycle. As long as there are no obstructions, the gate closes by gravity.

- The machine makes one complete cycle and returns to "top of stroke" and stops.

- The gate opens, after the cycle has stopped.

"B" Gate Sequence of Operation. Type "B" Gates protect the operator during the downstroke only. The gate starts to open before the crankshaft rotation is complete (generally after 180° crankshaft rotation). The gates must open on the upstroke of the machine cycle before the crankshaft rotation is complete.

The "B" gate only protects the operator on the down-stroke of the press slide. The following is a typical sequence of operation of a complete cycle on a press which uses a "B" gate.

- Initiate the cycle. As long as there are no obstructions, the gate closes by gravity.

- Once the machine reaches the portion of the stroke where the pinch point has been eliminated and before the stroke has stopped, the "B" gate and the slide go up at the same time.

Knowledge Check Choose the best answer for the question.

3-9. Which of the following is a moveable barrier that protects the operator at the point of operation before the machine cycle can be started?

You forgot to answer the question!