Radiofrequency Presence-Sensing Devices

A radiofrequency presence-sensing device is often mounted on part-revolution power presses.

Key Features of Radiofrequency Presence-Sensing Devices

The key features of a radiofrequency presence-sensing device include the following:

- Prevents machine operation: Stops the machine if the probe detects any obstruction in the danger zone.

- Ensures safe hand position: Requires the operator to keep hands on control buttons, away from moving parts.

- Automatic safety check: The device checks for presence before allowing the press to cycle.

- Reduces accidental injury: Minimizes risk of operator hand being inside danger area during machine operation.

- Reliable detection: Uses radiofrequency signals to sense presence without physical contact.

Examples

- Part-revolution power presses with radiofrequency probes that stop the press if hands or objects block the probe.

- Metal stamping machines that use presence-sensing devices to prevent operation when an obstruction is detected.

- Assembly line presses equipped with radiofrequency sensors to ensure operator hands are clear before starting.

- Punching machines using contact bars that sense when material or hands are incorrectly positioned.

- Specialized machines in manufacturing that rely on radiofrequency sensing to maintain operator safety during repetitive cycles.

| Safeguarding Action | Advantages | Limitations |

|

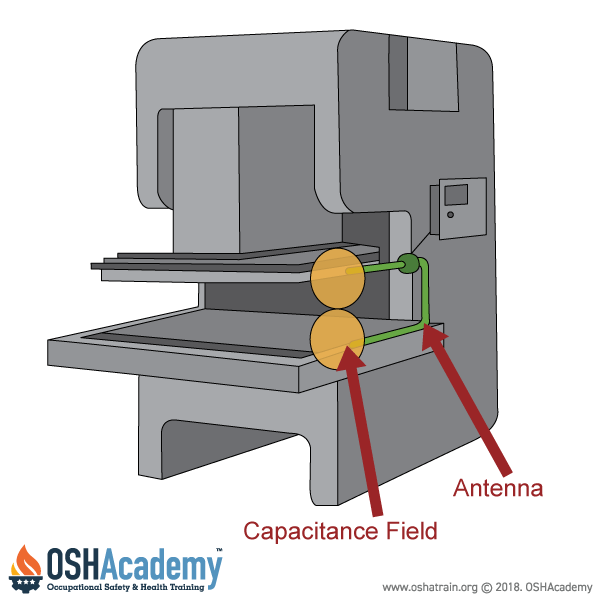

Machine cycling will not start when the capacitance field is interrupted When the capacitance field is disturbed by any part of the operator's body during the cycling process, immediate machine breaking is activated |

Can allow freer movement for operator |

Does not protect against mechanical failure Antennae sensitivity must be properly adjusted; this adjustment must be maintained properly Limited to machines that can be stopped |

Knowledge Check Choose the best answer for the question.

3-3. What is the main purpose of a radiofrequency presence-sensing device?

You forgot to answer the question!