Hazardous Conditions

A hazardous condition is any situation, object, or material that has the potential to cause harm, injury, or illness to people in the workplace.

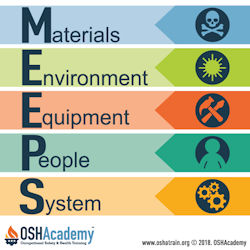

All workplaces contain hazardous conditions that fall into one or more of five categories. It is easy to remember the categories by using the "MEEPS" acronym:

- Materials: Any material, such as chemicals, wood, metals, fibers, and plastics, may present hazards.

- Environments: Two categories of hazardous environments exist:

- Physical – hazardous atmospheres, excessive noise, temperature extremes, ergonomic hazards.

- Psychosocial - inadequate time, unreasonable schedules, unobtainable goals, or any form of intimidation or coercion can create a high level of anxiety and distress, leading to illness.

- Equipment: Defective tools, unguarded equipment, complex machinery. Anything that moves is hazardous.

- People: Lack of knowledge, skills, or abilities represent hazardous states of being. A poorly trained worker, physical weakness, limited cognitive ability, distraction, or any kind of stress, etc., can all create "walking hazardous conditions."

- System: Poorly designed and deployed programs, policies, plans, processes, procedures, and practices are ultimately the conditions that cause most accidents.

In December 2025, an Oregon OSHA inspection at a manufacturing facility found hazardous conditions involving improperly installed/damaged storage racks (including unanchored baseplates) and an unguarded belt sander. One practical way to organize what went wrong is the MEEPS method: Materials, Environments, Equipment, People, and System.

- Materials: Heavy raw materials were stored at height on racks. If materials shift or fall, the mass creates a serious struck-by/crushing hazard.

- Environments: Active warehouse/manufacturing areas with forklift traffic and employees working near rack aisles increased exposure. Limited separation between people and elevated loads raises risk.

- Equipment: Storage racks were not properly maintained/installed (e.g., baseplates not anchored, damaged components). A belt sander had unguarded moving parts, creating a clear hand/finger injury hazard.

- People: Employees accessed stored materials by hand and with forklifts. Without consistent hazard recognition and stop-work expectations, workers can be exposed to “walking hazards” (unsafe decisions in unsafe areas).

- System: The inspection outcome suggests breakdowns in the safety management process—routine rack inspection/maintenance, hazard reporting, corrective-action tracking, and enforcement of machine guarding requirements. Oregon OSHA cited the rack issue as a willful violation (hazard known, not corrected) and issued a second violation for the unguarded machine, totaling $28,478 in penalties.

Bottom line: MEEPS makes it harder to miss the obvious. This case wasn’t one “random hazard”—it was multiple hazard categories lining up at once.

Knowledge Check Choose the best answer for the question.

5-3. Which hazard category do poorly trained workers fit into?

You forgot to answer the question!