Machine Guard Materials

When designing machine guards, selecting the right material is crucial for ensuring safety, visibility, durability, and resistance to environmental conditions.

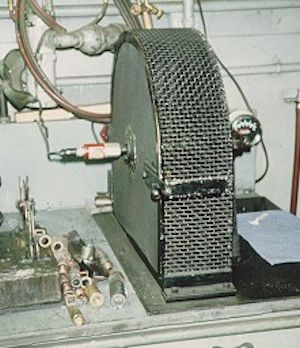

Metal Guards

In most cases, metal is the best choice for machine guards. Metal guards are strong, durable, and resistant to wear, making them suitable for high-risk areas with moving machinery parts.

Framework: The frame of a metal guard is typically built using structural steel, such as:

- Angle iron – L-shaped metal that provides strong support.

- Pipe – Round steel tubing that offers structural strength.

- Bar or rod stock – Solid pieces of metal shaped into straight lines or curves.

Filler Materials: These are used within the frame to block access while allowing visibility and airflow. Examples include:

- Expanded metal – A sheet of metal cut and stretched to form a mesh-like pattern.

- Perforated metal – A sheet with evenly spaced holes punched through it.

- Solid sheet metal – Used when maximum protection is needed, though it limits visibility.

- Wire mesh – Metal wires woven together to create a net-like barrier, often used around moving belts or pulleys.

Plastic or Safety Glass

In situations where it's important to see the machine's operation, clear plastic or shatter-resistant safety glass may be used. These materials:

- Provide visibility for inspection and monitoring.

- Are suitable for guards around less hazardous machinery or as windows in larger metal guards.

Example: A CNC machine may have a metal guard with a clear polycarbonate window so the operator can safely observe the cutting process.

Wooden Guards

Generally, wood is not recommended for machine guarding because:

- It is flammable, posing a fire risk.

- It lacks the strength and durability needed for industrial environments.

However, there are exceptions. In certain environments, such as those involving corrosive chemicals, metal can quickly degrade. In these cases, wood might be used as a temporary or specially treated guard.

Example: In a chemical plant where acid vapors corrode metal rapidly, a sealed wooden guard might be used to provide short-term protection while longer-term solutions are developed.

Knowledge Check Choose the best answer for the question.

5-7. Which material may be the best for machine safeguards if corrosive chemicals are present?

You forgot to answer the question!