Mechanical Energy Hazards

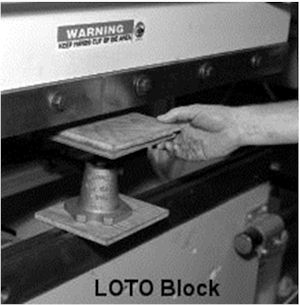

The image shows safety blocks being used as an additional safeguard on a mechanical power press, even though the machine has been locked out. The safety blocks prevent the ram from coming down under its own weight.

Safety Block

Pneumatic and Hydraulic Energy Sources: The second image shows a lockout valve. The lever-operated valve used during repair or shutdown to keep a machine or its components from operating can be locked open or shut.

Lockout Valve

Before the valve can be opened, everyone working on the machine must use his or her own key to release the lockout.

A sliding-sleeve valve exhausts line pressure at the same time it cuts off the air supply. Valves used to lock out pneumatic or hydraulic-powered machines should be designed to accept locks or lockout adapters and should be capable of "bleeding off" pressure residues that could cause any part of the machine to move.

Electricity: All power sources for machines are potential sources of danger. When using electrically powered or controlled machines, for instance, the equipment as well as the electrical system itself must be properly grounded. Replacing frayed, exposed, or old wiring will also help to protect the operator and others from electrical shocks or electrocution. High pressure systems, too, need careful inspection and maintenance to prevent possible failure from pulsation, vibration, or leaks. Such a failure could cause, among other things, explosions or flying objects.

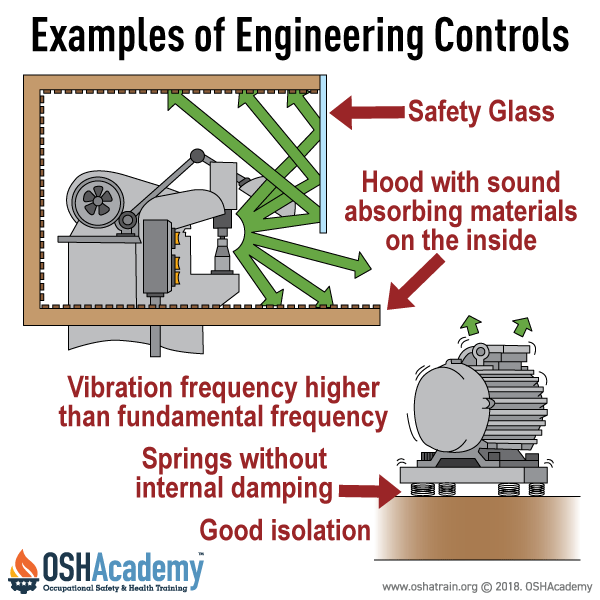

Noise: Machines often produce noise (unwanted sound) which can result in a number of hazards to workers.

Noise can startle and disrupt concentration, and can interfere with communications, thus hindering the worker's safe job performance. Engineering controls such as sound-dampening materials, and personal protective equipment can help control the harmful effects of noise. Administrative controls that involve removing the worker from the noise source can also be an effective measure when feasible.

Harmful Substances: Workers in the vicinity of machines that require the use of cutting fluids, coolants, and other potentially harmful substances may need protection. These substances can cause ailments ranging from dermatitis to serious illnesses and disease. Specially constructed safeguards, ventilation, and protective equipment and clothing are possible temporary solutions to the problem of machinery-related chemical hazards until these hazards can be better controlled or eliminated from the workplace.

Knowledge Check Choose the best answer for the question.

5-3. Which step should a worker take to reduce the risk of electrical shock from machinery?

You forgot to answer the question!