Elimination and Substitution

In most cases, the preferred approach is to eliminate the source of hazardous noise. When elimination is not possible, substitution of the loud equipment for quieter equipment may be the next best alternative to protect workers from hazardous noise.

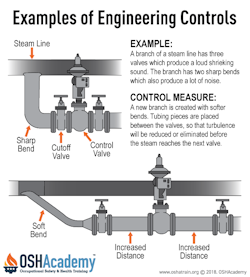

Engineering Controls

Engineering controls that reduce sound exposure levels are available and technologically feasible for most noise sources. Simple engineering noise control solutions can reduce the noise hazard to the extent that audiometric testing, a hearing conservation program, and the use of hearing protectors, are not necessary.

To reduce the noise levels, two engineering control strategies are used:

- designing or modifying equipment, or

- making related physical changes at the noise source or along the transmission path.

Equipment Design and Modification

Examples of effective engineering controls that focus on design or modification include:

- Replace noisy equipment with quieter models: This can involve replacing old, noisy equipment with newer, quieter models that meet noise level requirements. Design changes can be made to reduce the level of noise as a result of equipment operation. (see image)

- Install mufflers or silencers: These can be used to reduce the noise levels of equipment that generates noise, such as compressors, engines, or ventilation systems.

- Conduct regular maintenance: Regular maintenance of equipment can help reduce noise levels by ensuring that equipment is working properly and not producing excessive noise.

Knowledge Check Choose the best answer for the question.

3-3. Which of the "Hierarchy of Controls" categories involves designing or modifying equipment, or making related physical changes at the noise source?

You forgot to answer the question!