Interlocked Guards

Interlocked guards protect workers from dangerous parts of a machine. When an interlocked guard is opened or removed, the machine’s power or control system automatically shuts off or disengages. This means the machine cannot operate or be started until the guard is securely back in place.

Interlocked Lathe Guard

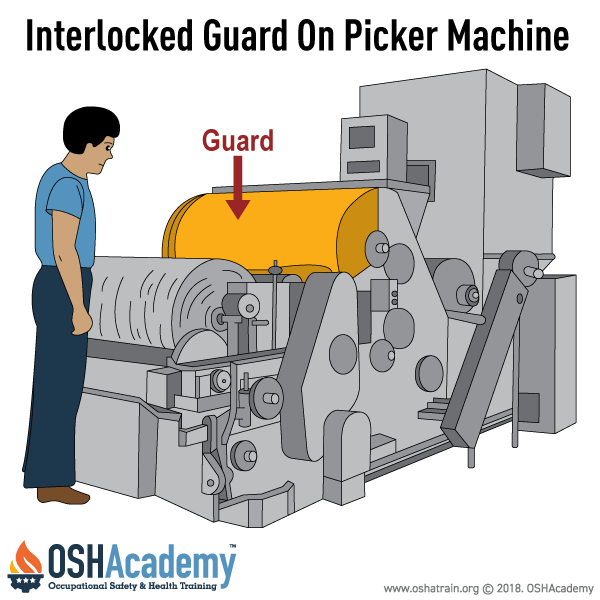

For example, the picker machine (see image) shows an interlocked barrier guard. The guard cannot be raised while the machine is running. If someone tries to open the guard, the machine will immediately stop. Also, the machine will not restart if the guard remains open. This prevents accidents caused by workers reaching into moving parts.

Materials and Applications

To be effective, every movable guard on a machine must have an interlock system to prevent workers from getting injured by exposed parts.

The materials listed below for machine guards must be sturdy enough to withstand impacts and regular use over time.

- Sheet metal: Commonly used for its strength and ability to cover large areas.

- Wire mesh: Allows visibility while providing protection from flying debris or contact with moving parts.

- Bars: Used to create rigid barriers that prevent access to dangerous areas.

- Plastic: Lightweight and durable, often used where transparency or impact resistance is needed.

- Other durable substances: Materials like reinforced composites may be used depending on the application and environment.

- Interlock systems: Ensure guards cannot be removed or opened without stopping the machine, enhancing worker safety.

Interlocked guards can work using different types of power, such as electrical, mechanical, hydraulic, or pneumatic systems. Sometimes, a combination of these power types is used for more reliable protection. Important safety rules for interlocked guards include:

- Inching, an intermittent brief motion imparted to the slide, must be allowed so the machine can be moved in small steps by remote control if necessary, without bypassing safety features.

- The machine must not restart automatically when the guard is replaced to avoid unexpected movement.

- All movable guards must be interlocked to prevent occupational hazards.

The guard itself may be made from strong materials like sheet metal, wire mesh, bars, plastic, or other durable substances. These materials must be sturdy enough to withstand impacts and regular use over time.

In comparison, Fixed guards are usually preferred because they are simpler and more permanent. Fixed guards require less maintenance and provide continuous protection without relying on mechanical or electrical systems.

Examples

- A robotic welding machine uses an interlocked guard that stops the robot when the guard door is opened, preventing workers from being hit by the moving arm.

- A conveyor belt system has an interlocked cover over the rollers; if the cover is lifted, the belt immediately stops to avoid hand injuries.

- A hydraulic press includes a guard with an interlock switch so the press cannot operate unless the guard is closed, preventing crushing accidents.

These examples show how interlocked guards help maintain safety by controlling machine operation based on guard position.

| Safeguarding Action | Advantages | Limitations |

|

Shuts off or disengages power, stops the moving parts and prevents starting of the machine when the guard is open; should require the machine to be stopped before the worker can reach into the danger area |

Can provide maximum protection Allows access to the machine for removing jams without time consuming removal of the fixed guards |

Requires careful adjustment and maintenance May be easy to disengage |

Knowledge Check Choose the best answer for the question.

2-3. Which type of guard automatically shuts off or disengages when it is opened or removed?

You forgot to answer the question!