Noise

Hazard Controls

Hierarchy of Controls (HOC) are the first line of defense against excessive noise exposure. The use of these controls should aim to reduce the hazardous exposure to the point where the risk to hearing is eliminated or minimized. With the reduction of even a few decibels, the hazard to hearing is reduced, communication is improved, and noise-related annoyance is reduced. There are several ways to control and reduce worker exposure to noise in a workplace.

The first three HOC strategies (1–3) below focus on reducing the severity of an accident by directly eliminating or reducing hazards.

1. Elimination: Elimination completely removes noise hazards so they cannot cause an accident or injuries. This is the most effective prevention strategy, and should be implemented when possible. Examples include:

- Decommissioning and removing outdated, noisy equipment that cannot be repaired

- Redesigning production processes so they no longer require loud operations

- Relocating certain work tasks to an off-site facility that does not affect other workers

- Automating tasks to eliminate manual operations that create noise

2. Substitution: The purpose of substitution is to replace hazardous materials, equipment, or processes with safer alternatives. Examples include:

- Replacing an air-powered tool with a quieter electric model

- Replacing noisy gas-driven equipment with quieter electric equipment

- Using conveyor belts instead of mechanical rollers that create constant noise

- Switching from metal components to composite or rubber materials that generate less sound

- Choosing quieter fans, pumps, or motors when upgrading equipment

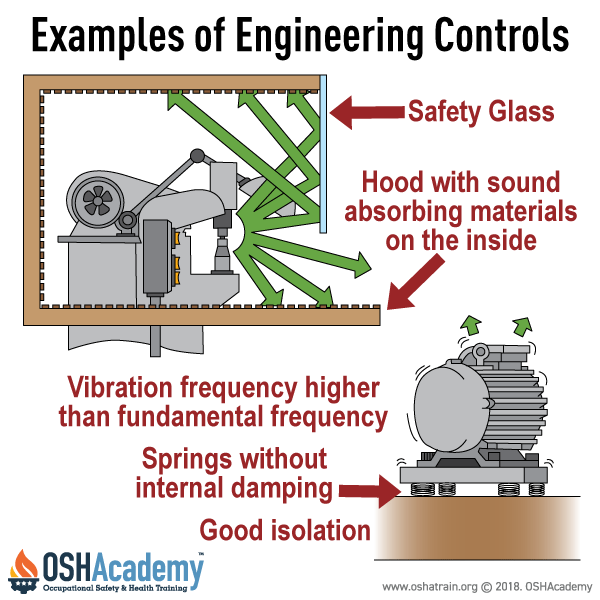

3. Engineering Controls: Engineering controls involve modifying or replacing equipment, or making physical changes at the noise source or along the transmission path to reduce the noise level at the worker's ear.

In some cases, a relatively simple engineering noise control solution reduces the noise hazard enough that further requirements of the OSHA Noise Standard (e.g., audiometric testing, hearing conservation program, provision of hearing protectors, etc.) are not necessary. Examples of inexpensive, effective engineering controls include:

- Enclosing or isolating loud machines in soundproof rooms or booths

- Installing acoustic barriers, baffles, or panels around noisy equipment

- Adding silencers, mufflers, or dampers to air vents, fans, or exhaust systems

- Using vibration-absorbing mounts to reduce structure-borne noise

- Installing acoustic tiles, wall panels, and ceiling materials to absorb sound reflections

- Designating "quiet zone" areas where loud machinery cannot be installed

- Maintaining machines regularly by lubricating moving parts and replacing worn components

Knowledge Check Choose the best answer for the question.

5-5. A factory installs soundproof booths around noisy machines. What type of noise control does this represent?

You forgot to answer the question!