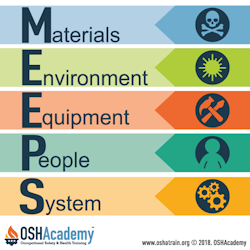

Hazard Categories

To help identify workplace hazards, categorize them into these five easy-to-remember categories:

The Five Hazard Categories

- The first three categories, Materials, Environment, and Equipment, represent hazardous workplace conditions. Research and historical data indicate that hazardous conditions account for only a small percentage of all workplace accidents.

- The fourth category, People, describes employee behaviors in the workplace that contribute to or cause a great majority of all workplace accidents.

- The fifth category, Systems, contributes to or causes virtually all of the hazardous conditions and unsafe behaviors described in the other four categories.

Materials

Materials include liquids, solids and gases that can be hazardous to employees.

- Liquid and solid chemicals, such as acids, bases, solvents, and explosives, can produce harmful effects.

- Raw materials, including metals, wood, and plastics, often purchased in bulk for manufacturing, can cause injuries or fatalities.

- Gases, like hydrogen sulfide and methane, may be extremely hazardous if leaked into the atmosphere.

Environment

The environment includes the general area where employees work, ranging from individual workstations to entire construction sites.

- Poor facility design, hazardous atmospheres, temperature, and/or noise can cause stress.

- Workplaces with excessive heat, cold, dust, dirt, clutter, or moisture should be modified to reduce these adverse conditions.

- Extreme noise that can damage hearing should not be present.

- Inadequately designed workstations, such as those not suited for the height of the employees using them, contribute to an unsafe work environment.

Equipment

Equipment includes a variety of machinery and tools used to produce or process goods.

- Improperly guarded hazardous equipment, especially around moving parts, can result in injuries or fatalities.

- Lack-of a preventive maintenance program will make it difficult to ensure equipment operates properly.

- In the absence of a corrective maintenance program, faulty or hazardous equipment might not receive timely repairs, posing risks to workers.

- Tools that are poorly maintained, improperly repaired, or misused significantly increase the likelihood of accidents. It is well-known among maintenance personnel that incorrect or unsafe tool use, especially with damaged tools, poses serious dangers.

People

People include employees, management, and others in the workplace.

- Unsafe employee behaviors include taking short cuts or not using personal protective equipment.

- Employees working while fatigued, under the influence of drugs or alcohol, distracted, or in a rush can become 'walking hazards,' posing risks to themselves and others.

System

This last category includes safety leadership and management system inputs, processes, and outputs.

- Weaknesses within the safety leadership and management system that may contribute to the other hazard categories.

- Ineffective principles, policies, programs, plans, procedures, practices, and performance.

Knowledge Check Choose the best answer for the question.

2-2. Which hazard category includes liquid and solid chemicals?

You forgot to answer the question!