Materials and Hardware

Employers must provide protective materials and hardware required for LOTO procedures.

They must provide locks, tags, chains, wedges, key blocks, adapter pins, self-locking fasteners, or other hardware for isolating, securing or blocking machines or equipment from their energy sources.

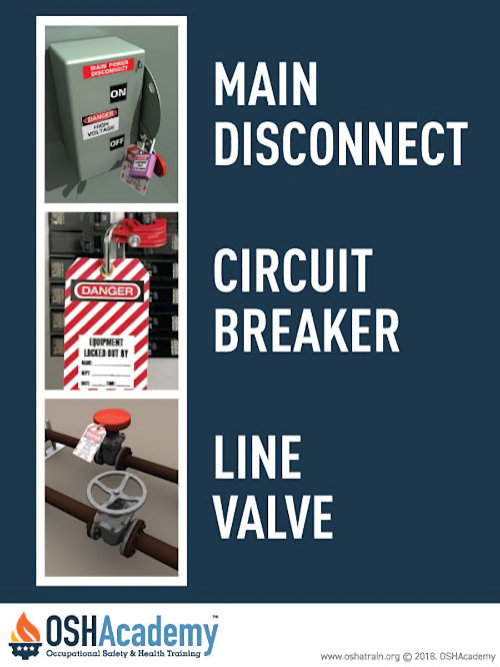

As mentioned in Module 1, lockout/tagout devices hold energy-isolation devices in a safe or "off" position. To the right are a few examples of locks and tags used to lockout or tagout main disconnects, line valves, and circuit breakers.

Hardware Requirements

There are specific requirements for LOTO devices to make sure they fulfill the purpose for which they are used. They must ensure authorized employees are safe from injury while working on equipment and machinery.

1910.147(c)(5) Protective materials and hardware.

1910.147(c)(5)(i): Locks, tags, chains, wedges, key blocks, adapter pins, self-locking fasteners, or other hardware must be provided by the employer for isolating, securing, or blocking machines or equipment from energy sources.

1910.147(c)(5)(ii): Lockout devices and tagout devices must be singularly identified; must be the only devices used for controlling energy; must not be used for other purposes; and must meet the following requirements:

- 1910.147(c)(5)(ii)(A) Durable.

- 1910.147(c)(5)(ii)(A)(1): Lockout and tagout devices must be capable of withstanding the environment to which they are exposed for the maximum period of time that exposure is expected.

- 1910.147(c)(5)(ii)(A)(2): Tagout devices must be constructed and printed so that exposure to weather conditions or wet and damp locations will not cause the tag to deteriorate or the message on the tag to become illegible.

- 1910.147(c)(5)(ii)(A)(3): Tags must not deteriorate when used in corrosive environments such as areas where acid and alkali chemicals are handled and stored.

- 1910.147(c)(5)(ii)(B): Standardized. Lockout and tagout devices must be standardized within the facility in at least one of the following criteria: Color; shape; or size. For tagout devices, print and format must also be standardized.

- 1910.147(c)(5)(ii)(C) Substantial.

- 1910.147(c)(5)(ii)(C)(1): Lockout devices must be substantial enough to prevent removal without the use of excessive force or unusual techniques, such as with the use of bolt cutters or other metal cutting tools.

- 1910.147(c)(5)(ii)(C)(2): Tagout devices and their means of attachment must be substantial enough to prevent inadvertent or accidental removal. Tagout device attachment means must be non-reusable, attachable by hand, self-locking, and non-releasable with a minimum unlocking strength of no less than 50 pounds and have the general design and basic characteristics of being at least equivalent to a one-piece, all-environment-tolerant nylon cable tie.

- 1910.147(c)(5)(ii)(D): Identifiable. Lockout and tagout devices must indicate the identity of the employee applying the devices.

1910.147(c)(5)(iii): Tagout devices must warn against hazardous conditions if the machine or equipment is energized and must include a legend such as the following: Do Not Start, Do Not Open, Do Not Close, Do Not Energize, Do Not Operate.

Knowledge Check Choose the best answer for the question.

5-1. Lockout/tagout devices hold _____ in a safe or "off" position.

You forgot to answer the question!