Written Exposure Control Plan (ECP)

The first step, and a very important OSHA requirement, in making sure exposure to silica dust is controlled is to design, develop, and deploy an effective Exposure Control Plan (ECP).

This plan outlines how a company will protect its workers from respirable crystalline silica, which can cause serious health problems like lung disease, silicosis, and cancer.

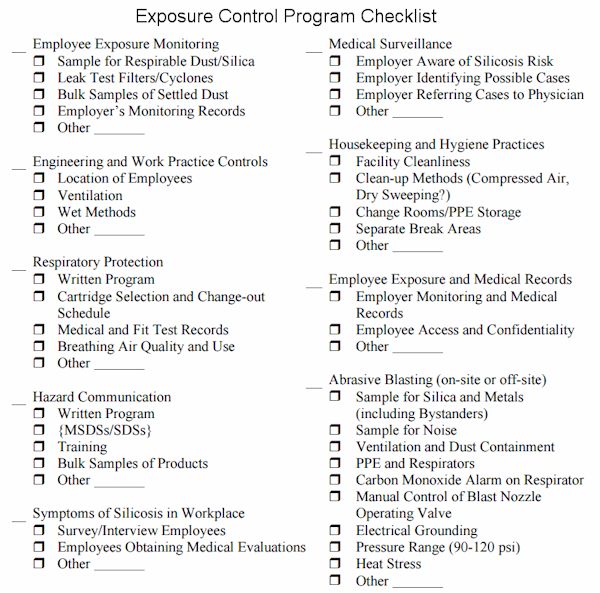

Exposure Control Program Checklist

An effective Exposure Control Plan should include the following elements:

-

Description of Tasks with Silica Exposure:

The plan should clearly describe all tasks in the workplace where workers may be exposed to respirable crystalline silica.

Example: "Cutting concrete blocks using a handheld power saw exposes workers to silica dust." -

Engineering Controls, Work Practices, and Respiratory Protection:

For each task that exposes workers to silica, the plan must list the methods used to reduce exposure. These include ventilation systems, water sprays, or vacuum dust collection. When these controls are not enough, the plan should include the type of respirator used.

Example: "Use of a saw equipped with an integrated water delivery system and N95 respirators for employees during dry cutting tasks." -

Housekeeping Measures:

The plan must explain how the workplace is kept clean to reduce dust build-up. It should prohibit dry sweeping or using compressed air unless proper ventilation or wet methods are in place.

Example: "Wet mopping is required after tile removal to prevent dust from becoming airborne." -

Access Control Procedures:

The plan should describe how access to work areas is limited when necessary. This prevents unprotected workers from being exposed.

Example: "Warning tape is used to restrict access to the masonry cutting zone. Only authorized workers wearing PPE may enter."

Below is a checklist to help evaluate whether the Exposure Control Plan is being followed and remains effective.

Exposure Control Plan (ECP) Evaluation Checklist – Fillable Form

Fill out the form and generate a printable PDF using the "Print" button to open the a dialog that allows your save the filled form as a PDF.

Knowledge Check Choose the best answer for the question.

1-4. What is the first step, and a very important OSHA requirement, in making sure exposure to silica dust is controlled?

You forgot to answer the question!