11.G Batteries and Battery Charging.

11.G.01 Batteries must be stored in enclosures with outside vents or in well-ventilated rooms and be so arranged as to prevent the escape of fumes, gasses, electrolyte spray, or liquid electrolyte into other areas.

11.G.02 Provisions must be made for sufficient diffusion and ventilation of gases from storage batteries to prevent the accumulation of explosive mixtures.

11.G.03 Battery storage and handling.

- Racks and trays must be substantial and must be treated to make them resistant to the electrolyte.

- Floors must be of acid resistant construction or protected from accumulation of acid.

- Facilities for quick drenching of the eyes and body must be provided for emergency use within 25 ft (7.6 m) of battery handling areas. > See Section 06.B.02.b.

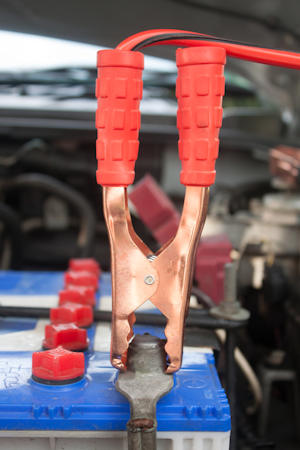

- Use only insulated tools in the battery area to prevent accidental shorting across battery connections.

- PPE must be used as prescribed in Section 11.G.06 and Section 5.

- For lead acid batteries, bicarbonate of soda to neutralize any acid spillage [1 lb/gal (0.1 kg/L) of water] must be provided for flushing and neutralizing spilled electrolyte and for fire protection.

11.G.04 Battery charging.

- Battery charging installations must be located in areas designated for that purpose.

- Charging apparatus must be protected against physical damage.

- When charging batteries, the vent caps must be kept in place to avoid spray of electrolyte. Care must be taken to assure vent caps are functioning.

- Prior to charging batteries, the electrolyte level must be checked and adjusted to the proper level if necessary.

11.G.05 Exit route from battery area must remain unobstructed.

11.G.06 PPE. The following must be available and used for safe battery handling.

- Goggles and faceshields appropriate to the chemical and electrical hazard;

- Acid-resistant rubber gloves;

- Protective rubber aprons and safety shoes;

- Lifting devices of adequate capacity, when required.

11.H Hazardous (Classified) Locations.

11.H.01 Locations of electrical equipment and wiring must be classified on the properties of the flammable vapors, liquids or gases, or combustible dusts or fibers that may be present and the likelihood that a flammable or combustible concentration or quantity is present. In classifying locations, each room, section, or area must be classified on an individual basis in accordance with the definitions given in Table 11-2 and NEC Article 500. These hazardous locations within the facility, as designated, must be documented by the employer.

| Class I Gasses, Vapors or Liquids (A, B, C and D) | |

|---|---|

| Division 1 | Division 2 |

| Normally explosive and hazardous | Not normally present in an explosive concentration (but may accidentally exist) |

| Zone 0 (IEC Stds) | Zone 1 (IEC Stds) |

| Class II Dusts (E, F and G) | |

| Division 1 | Division 2 |

| Ignitable quantity of dust that is normally or may be, in suspension or conductive dust may be present | Dust not normally suspended in an ignitable concentration (but may accidentally exist). Dust layers are present. |

| Class III Fibers or Flyings (H) | |

| Division 1 | Division 2 |

| Handled or used in manufacturing | Stored or handled in storage (exclusive of manufacturing). |

- A - Acetylene

- B – Hydrogen

- C - Ethyl-ether vapors, ethylene, etc

- D –Hydrocarbons, fuels, solvents, etc

- E - Metal dust (conductive* and explosive);

- F - Carbon dusts (some are conductive* and all are explosive)

- G - Flour, starch, grain, Combustible Plastic or Chemical Dusts (explosive)

- H –Textiles, woodworking, etc.,(easily ignitable, not likely to be explosive)

*Note: Electrically conductive dusts are dusts with a resistivity less than 105 OHM-centimeter

11.H.02 All equipment, wiring methods, and installations of equipment in hazardous (classified) locations must be either listed as intrinsically safe, listed for the hazardous location, or demonstrated to be safe for the location.

11.H.03 Only equipment wiring and installation of equipment in hazardous locations must be permitted in those hazardous (classified) locations.

11.H.04 Equipment and wiring listed for the hazardous (classified) location must be approved not only for the class of location but also for the ignitable or combustible properties of the specific gas, vapor, dust, or fiber that will be present.

- This equipment must be marked to show the class, group, and operating temperature or temperature range for which it is approved.

- With the following exceptions, the temperature marking must not exceed the ignition temperature of the specific gas or vapor to be encountered.

- (1) Equipment of the non-heat producing type (e.g., junction boxes and conduit) and equipment of the heat producing type having a maximum temperature not more than 212ºF (100ºC) need not have a marked operating temperature or temperature range.

- (2) Fixed lighting fixtures marked for use in Class I, Division 2 or Class II, Division 2 locations need not be marked to indicate the group.

- (3) Fixed general-purpose equipment in Class I locations, other than lighting fixtures, that is acceptable for use in Class I, Division 2 locations need not be marked with the class, group, division, or operating temperature.

- (4)Fixed dust-tight equipment, other than lighting fixtures, that is acceptable for use in Class II, Division 2, and Class III locations need not be marked with the class, group, division, or operating temperature.

11.H.05 Equipment that is safe for the hazardous location must be of a type and design that will provide protection from the hazards arising from the combustibility and flammability of vapors, liquids, gases, dusts, or fibers involved.

11.H.06 Equipment approved for a specific hazardous location must not be installed or intermixed with equipment approved for another specific hazardous location.

11.H.07 All wiring components and utilization equipment must be explosion proof (vapor, dust, or fiber tight) and must be maintained in that condition.

- There must be no loose or missing screws, gaskets, threaded connections, or other impairments to this tight condition.

- Conduits must be threaded and made wrench-tight: where it is impractical to make a threaded joint tight, a bonding jumper must be used.

Knowledge Check Choose the best answer for the question.

11-7. How close must facilities for quick drenching of the eyes and body located for emergency use in battery handling areas?

You forgot to answer the question!